Hot - Cold Insulation Jackets

INSJACK® insulation jackets, produced by INSPRO at its own facilities with unique designs, are a remarkable solution in terms of energy saving, process temperature maintenance and personnel safety!

Using only the highest quality materials and dedicated craftspeople, INSPRO’s removable insulation covers are optimum solutions for various thermal and acoustic insulation needs. The INSJACK® removable insulation covers can be made with various insulation fillers (fiberglass, superwool, aerogel, etc.) using a variety of enclosures and closure systems to meet the insulation requirements needed.

INSJACK® insulation jackets are used in a variety of applications where energy saving and temperature maintenance is a concern such as valves, turbines, piping, exhaust stacks, expansion joints, diesel turbo covers, product tanks, acoustic applications, insulating sleeves and heat exchangers.

INSJACK® insulation jackets are specially designed for fittings and equipment that require periodic maintenance during operation or are likely to be damaged. INSJACK® insulation jackets, which are suitable for use in outdoor and indoor environments, provide high efficiency hot and cold insulation and meet the initial investment cost in a short period of time since they are used.

- Valve

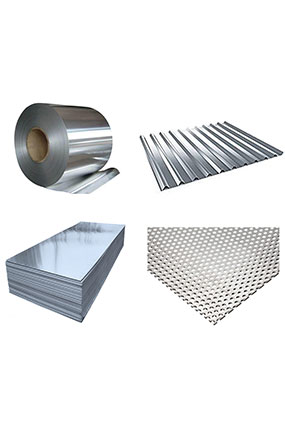

- Flange

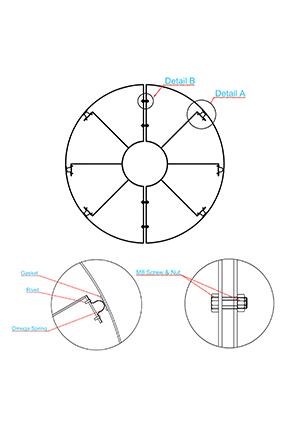

- Pipe

- Expansion Joint

- Strainer

- Actuator

- Tank

- Fan

- Pump

- Exhaust Line

- Manhole

- Furnace

Maintenance of fittings (valves, flanges, etc.) with removable insulation jacket can be easily done without damaging the existing insulation.

Unlike most removable insulation blankets, INSJACK® covers fit the best because they are manufactured in the actual shape of the equipment, whether that is a single valve, flange, tank, turbine, exhaust, fan, pump or an entire piping system.

Installation of removable insulation covers is so easy as there is no need for any special equipment or tool. Any technical personnel can easily access equipment for maintenance and reinstall the insulation cover. INSJACK® covers allow to insulate important components without sacrificing employee efficiency or ease of access.

We custom engineer every removable insulation cover for each project, so INSJACK® products will fit any system perfectly. And INSPRO quality design and manufacture means that you achieve long product life with the highest level of insulation as well as energy efficiency.

The covers are thoroughly inspected to assure durable seams and complete insulation coverage. Such inspections include thermal imaging which is effectively a picture of thousands of surface temperature measurements, makes it easy to see where insulation is missing after failures such as thermal bridges or production defects.

Leakage, caused by any insulated fitting (valve, flange, etc.), can easily be detected with insulation jackets equipped with drainage and leakage indicator. In this way, the necessary actions can be taken and the possibility of corrosion under insulation (CUI) would be eliminated.