INS-FLEX®

Fabric expansion joints are flexible connection elements used to meet the mechanical and thermal resistance requirements, especially vibration and thermal expansion, of large-sized fluid transfer lines (air/gas ducts, etc.).

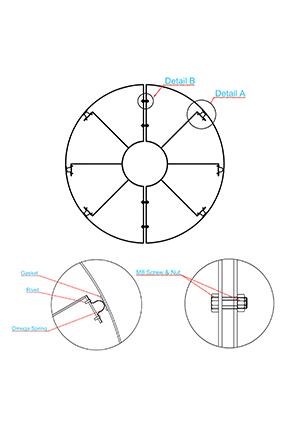

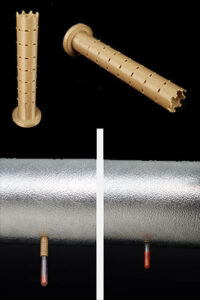

A fabric expansion joint is installed within the duct where movement will occur. A fabric expansion joint has two main components, sealing and the metal frames. The fabric sealing is a closed loop, like a belt, with its two edges clamped all around to the metal frames that are in turn connected to the end of ducting. As the ducting moves, the fabric belt allows movement while sealing. The fabric material must do this without tearing or leaking while sometimes being exposed to high temperatures and/or corrosive media.

Insflex® expansion joints can absorb axial, lateral, and angular movements as expected. Certainly with the best solution: Designing and manufacturing under the same roof.

- – Absorbing multi-directional movements

- – Sealing

- – Thermal insulation

- – Heat resistance, minimum and maximum service temperature

- – Fireproofing

- – Chemical resistance

While design an expansion joint, the above parameters are mainly considered, but many others such as pressure resistance, soundproofing, ergonomics and of course cost can also come into play, considering the process conditions of the duct and facility to be applied.

Multi-layer composite fabric expansion joint design (which must be performed by evaluating many parameters, especially thermal, chemical, and mechanical resistance requirements) is not a puzzle to be solved or played, it is pure ENGINEERING where different disciplines involved together!

Contact us to reach all consultancy, design, manufacturing, delivery, installation and commissioning services for fabric expansion joints that you need in construction or maintenance projects under the same roof.